Commercial Composting Solutions

Plastic may have taken much of the attention in recent times, but food waste continues to be a pressing issue affecting the environment.

Recent statistics show that the UK throws away roughly 9.5 million tonnes of food waste in a single year. Food waste from commercial premises (such as restaurants, retailers, manufacturers, and the hospitality sector) amounts to around 2.9 million tonnes annually. Volume-wise this is enough waste to fill Wembley Stadium twice (and a half).

According to WRAP (Waste and Resources Action Programme), food waste can cost UK restaurants a massive £682m per year.

When this food waste ends up in landfills, it emits large amounts of methane: a very potent greenhouse gas. The Environmental Defence Fund states that at least 25% of today’s global warming is driven by methane from human actions.

When it comes to the household or the individual, things may seem relatively simple: if you’re keen on gardening, it’s almost second nature to separate your food waste into a compost bin and make good use of it. Alternatively, you can separate your organic waste into a brown bin for collection.

However in the case of restaurants, hotels, schools, colleges and so on, you may well have a larger amount of food waste than you can deal with via the above options. There are also regulations to take into account and abide by for disposing of waste above a certain volume.

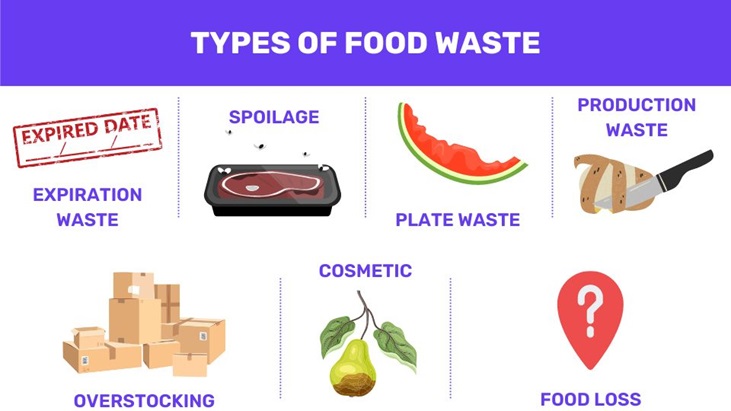

Food waste can quickly pile up, whether you’re a catering business or you have a high turnover of visitors or attendees who (being human) need to eat! It can take the form of peelings, leftovers, expired food or improperly prepared food.

Commercial composting methods are intended to deal efficiently with these large volumes of potential waste, while creating rich compost and soil improver at the same time.

The options available for a business or premises when it comes to food disposal include:

- Redistributing food to charities, food banks or community groups

- Collection from a waste collector, who will then either bring it to a facility for composting or incineration (sometimes creating energy from the incineration process)

- Arrange for their own transport to such a facility

- Sending waste to landfill: this is the least desirable option, with the UK government intending to stop all biodegradable waste from entering landfill by 2028

- Use an authorised composting unit to take care of the food waste ‘on-site’.

Commercial Joraform JK6200

View ProductIn-Vessel Composting

As you may have guessed, in-vessel commercial composting is where you place organic waste in a purpose-built sealed container. In-vessel composting takes place at waste facilities, but it is also an option for an individual business or premises to set up their own system on-site.

The enclosed, sealed nature of these units contains odours and ensures that they won't attract rodents or vermin. They are a practical and economic alternative to having your food waste collected or transported elsewhere.

What are the Benefits of Using a Commercial Composter?

- The end result of commercial composting is a rich, soil-like material that can be used as soil improver, fertiliser or mulch: whether it’s fed back into the business itself (if the business produces its own food) or supplied to local farmers, community groups, landscapers, or nurseries. This material nourishes crops and soil, providing a range of nutrients and leading to higher yields.

- Of course, it also means that food waste is kept out of landfill and methane emissions are thus reduced.

- Due to the amount of material that the Jora can ‘digest’, you can considerably reduce the amount of waste going into other containers, as well as the associated pickup or disposal costs.

- Additional revenue can be created by supplying the finished product to interested parties such as gardeners, horticulturists etc.

- On-site composting will contribute to the sustainability of your business. Sustainability is a concept or practice that encompasses the overall way that your business is run and the impact you have on the environment, the economy and society. When you think about it, carrying out your own commercial composting is a textbook example of this: there’s less food waste (environment), the economic burden of waste disposal is reduced (economy), and local farmers, landscapers etc can benefit from the finished product (social).

Joraform Commercial Composters

Joraform's commercial composting systems enable large-scale processing of food waste. With the addition of a JK6200 or its smaller cousin the JK5100, a business can become self-sufficient in how it deals with its own waste. These units include a built in grinder, automated wood pellet feed (to add carbon) and an aerator fan.

The end product is a nutrient-rich compost which can be used in landscaping or for growing food crops. It's a true closed-loop food recycling system.

How Does It Work?

The JK5100 uses a twin-chamber system to process organic waste. It can process 20 tonnes of food waste in a year, while its larger brother the JK 6200 is capable of dealing with twice that: equivalent to approximately 150 households.

Food and organic waste is added to the composter via a chute (or ‘hopper’ as it’s called) with an integrated grinder/shredder. The grinder ensures that the material has an even consistency as it enters the first chamber. This chamber is where most of the active breaking down of material occurs.

Sawdust pellets (similar to those used in a wood pellet boiler) are automatically mixed at the correct ratio to balance the high nitrogen food scraps with a high carbon material, leading to rapid composting. These pellets also reduce odours.

Mechanical arms periodically rotate the composter, airing the mixture and speeding up the decomposition process. Fresh organic material can still be added while this is going on, further fuelling the action. With these sealed biodigesters you can safely add raw or cooked food waste, including meat and fish.

After two weeks the mixture is then ejected into the second chamber. This is known as the ‘ripening chamber’ and has its own separate mixing process. The material at this point should be well broken down (yes, it’s a speedy process!), but separating it from further incoming waste gives it time to further ’ripen’ as it’s kept separate from incoming waste.

Grinding, mixing and aeration operations are variable and can be adjusted using a control panel. You can also get a view of what’s going on inside by using built-in inspection hatches. In total the turnaround from waste disposal to rich compost is a brisk 4 weeks.

Joraform Composter - JK800 (Fully Assembled)

View ProductThe JK800

Another option for medium-sized restaurants, cafes, guesthouses or community groups is the Joraform JK800. This is a tumbling composter design that can process from 100-160 litres of organic material a week.

Joraform tumblers are capable of rapid high-heat composting (up to 75 degrees °C); this is due to the high quality polyethylene foam insulation. The superior insulation abilities allow you to compost all year round.

The JK800 unit is made with durable galvanised steel and features two inner chambers. The chambers can be rotated easily using handles that are connected to the central axel. Once you have filled the first chamber, you cover it with a metal plate and allow the compost to mature as you start filling the second chamber.

Because the JK800 is enclosed, odour-free and raised off the ground, it won't attract rodents. You can also safely add materials such as cooked food, meat and fish, as the high temperatures will break them down and kill off pathogens etc.

The Joraform JK400

Smaller restaurants and premises can also consider the smaller model, the Joraform JK400. Again this is an insulated rotating composter with two chambers and works in the same way (except that the compartments of the JK800 are larger).

Like its bigger brother, the JK400 has built-in vents which ensure that plenty of air is added to the mixture. It can process from 50-80 litres of compost a week, or almost 2 tonnes annually. All in all you can have finished compost in just 6-8 weeks.

Joraform Compost Tumbler JK400

View ProductHow Sustainability Can Improve Your Business Image

Pursuing sustainability may seem more like an obligation than a benefit, but make no mistake: sustainability is increasingly an asset to a business, resulting in a positive reputation, good social connections and future-proofing against regulations further down the line etc.

Many consumers are looking for businesses that care about their social and environmental impact, and will gravitate towards the ones that ‘walk the walk’ so to speak.

If you’re interested in any of the Joraform commercial composters or tumblers, you can contact Niall at: niall@quickcrop.com for further info, or call 01788 298795

Refurbished Commercial Joraform JK5100

View Product